OilTools Services Engineered For Maximum Performance Through Superior Reliability Ruggedized Tool Delivers Reduced Downtime and Optimal Value

|

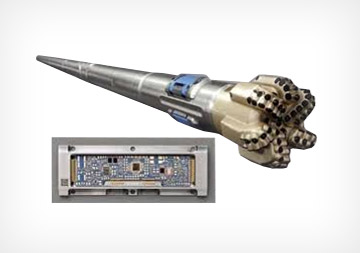

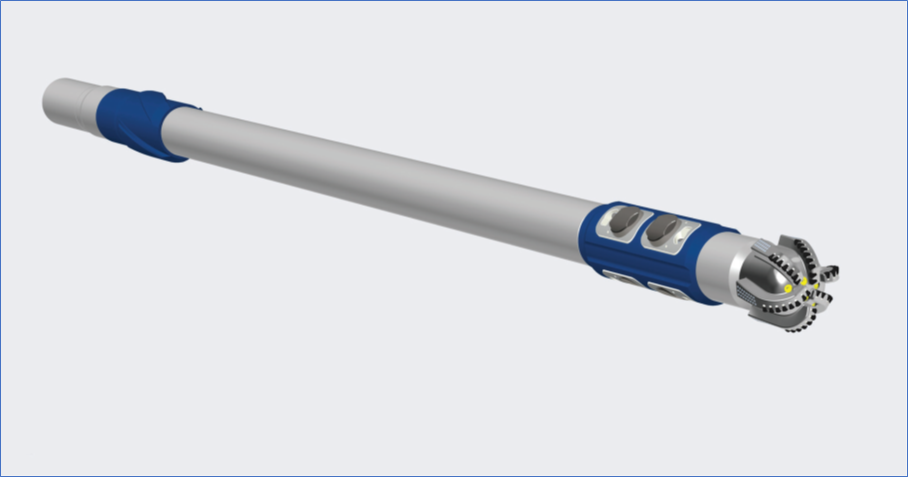

OilTools’s low-risk, high-return rotary steerable system (RSS) was engineered to meet/overcome unconventional formation drilling challenges, with an emphasis on reliably reaching total depth quickly, accurately, and with reduced financial risk. At an average of 12 to 13 feet in length, the robust solution is one of the shortest, most streamlined system on the market, reducing the risk of getting hung up while moving through extreme doglegs. The push-the-bit system delivers consistent, predictable build rates to drill a high-quality wellbore that can improve production over the long term. Because it was designed to eliminate as many failure points as possible, the fully contained system includes only 10 moving parts and requires no connections — even to MWD/LWD sensors—making it truly plug-and-play in virtually any BHA. To further reduce nonproductive time (NPT), all programming is completed by OilTools Services before it arrives onsite, reducing the chance of incorrect data entry. The system does not have a data port; thus, eliminating the potential for fluid invasion through the port. It is extremely robust, so it can withstand high-shock events and operate in harsh drilling applications, reducing the risk of damage seen with other rotary steerable systems. The potential for stuck pipe or excessive reaming has also been reduced since everything rotates. The RSS facilitates pinpoint accuracy with a three-axis, near-bit directional package. This continuously records inclination and azimuth, which is used to maintain control on target and allows the operator to drill to and remain in the sweet spot longer. OilTools Services understands that drilling high performing wells requires more than technology. To further improve performance and avoid NPT, an experienced onsite OilTools Services technician and 24/7 remote support are available when tools are downhole. A post-run report and analysis to maximize performance on future jobs is also provided

Applications

Benefits

•Increases flexibility with a universal plug and play system that is compatible with virtually any bit, motor, MWD/LWD sensor, fluid system, etc.

•Decreases NPT and risk of setup errors since it requires no programming at surface

•Improves your ability to get in and out of the hole without excessive preplanning and/or wiper trips

•Reduces safety risks by eliminating lithium batteries

Features

|